Ventilation Louvers by Om Engineers (Fabricator)

In the realm of architectural design, ventilation louvers have become indispensable elements, offering a perfect blend of functionality and aesthetics. These versatile structures not only facilitate airflow and ventilation but also add a touch of elegance to buildings, enhancing their overall appearance. As leading fabricators of ventilation louvers, Om Engineers (Fabricator) takes pride in delivering high-quality solutions that prioritize both performance and design. In this article, we delve into the world of ventilation louvers, exploring their features, benefits, and the exceptional craftsmanship offered by Om Engineers (Fabricator). Contact Us Here.

Understanding Ventilation Louvers

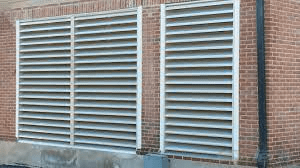

Ventilation louvers are architectural elements designed to allow the passage of air while providing protection against the ingress of water, debris, and insects. Typically installed on building facades, doors, windows, or mechanical systems, louvers consist of angled slats or fins spaced apart to create openings for airflow. These slats are oriented to deflect rainwater and direct airflow, ensuring optimal ventilation without compromising weather protection.

The Benefits of Ventilation Louvers

Ventilation louvers offer a range of benefits that contribute to the comfort, efficiency, and aesthetics of buildings:

- Improved Airflow: By allowing fresh air to enter and stale air to exit, ventilation louvers promote natural ventilation, which helps regulate indoor temperatures, reduce moisture buildup, and enhance occupant comfort.

- Weather Protection: Louvers are designed to withstand harsh weather conditions, including rain, wind, and snow, while preventing water ingress and protecting building interiors from water damage.

- Energy Efficiency: Proper ventilation provided by louvers can reduce the need for mechanical cooling and heating systems, resulting in energy savings and lower utility costs.

- Architectural Enhancement: Ventilation louvers come in a variety of styles, materials, and finishes, allowing architects to incorporate them seamlessly into building facades, enhancing visual appeal, and adding a distinctive architectural element.

Om Engineers (Fabricator): Your Partner for Ventilation Louvers

Om Engineers (Fabricator) specializes in designing and fabricating high-quality ventilation louvers that meet the diverse needs of architects, developers, and building owners. Our louvers are meticulously crafted using premium materials and cutting-edge manufacturing techniques to ensure durability, functionality, and aesthetic appeal.

Elevate Your Building with Ventilation Louvers from Om Engineers (Fabricator)

Whether you’re designing a commercial office building, a residential complex, or an industrial facility, ventilation louvers from Om Engineers (Fabricator) can enhance the performance and aesthetics of your project. With a commitment to excellence and customer satisfaction, we strive to deliver bespoke solutions that exceed expectations.

Contact Us Today!

Ready to elevate your building with ventilation louvers that combine functionality and elegance? Contact Om Engineers (Fabricator) today at +91 9922444544 to discuss your project requirements and discover how our expert team can bring your vision to life. Let us be your trusted partner in creating spaces that prioritize airflow, comfort, and architectural beauty.