Steel Grating Decks: Structural Integrity

In the realm of industrial and commercial construction, steel grating decks have become an indispensable element, offering superior strength, durability, and versatility for various applications. As a leading provider of structural solutions, Om Engineers (Fabricator) specializes in delivering high-quality steel grating decks that enhance the safety, functionality, and aesthetics of buildings and infrastructure projects. In this article, we delve into the world of steel grating decks, uncovering their features, benefits, and transformative impact on structural design.

Discover our innovative new project on Google Business Profile, showcasing our commitment to excellence and customer satisfaction.

Understanding Steel Grating Decks

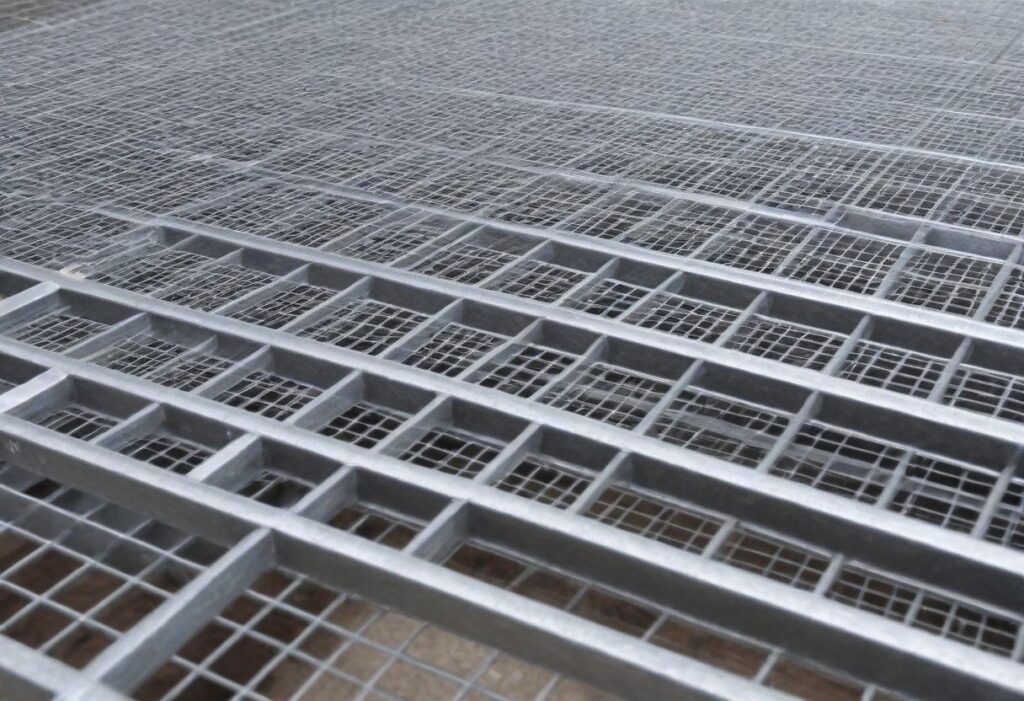

Steel grating decks, also known as bar grating decks, are structural elements composed of welded steel bars or crossbars arranged in a grid pattern. These decks are commonly used as flooring solutions in industrial facilities, mezzanines, catwalks, bridges, and outdoor platforms due to their exceptional load-bearing capacity, corrosion resistance, and open design that allows for efficient drainage and ventilation.

The Advantages of Steel Grating Decks

Steel grating decks offer a myriad of benefits that make them a preferred choice for architects, engineers, and contractors:

- High Strength: Steel grating decks are engineered to withstand heavy loads, making them ideal for applications where strength and durability are paramount.

- Enhanced Safety: The open design of steel grating decks allows for better visibility and airflow, reducing the risk of slips, trips, and falls in industrial environments.

- Corrosion Resistance: Steel grating decks are often galvanized or coated with protective finishes to resist corrosion, rust, and degradation from environmental factors, ensuring long-term performance and reliability.

- Customization Options: Steel grating decks can be customized in terms of size, shape, load rating, and surface texture to meet the specific requirements of each project.

Applications of Steel Grating Decks

Steel grating decks are used in a wide range of applications across various industries, including:

- Industrial Facilities: Steel grating decks are commonly installed as flooring solutions in manufacturing plants, warehouses, and processing facilities to provide stable platforms for heavy machinery and equipment.

- Commercial Buildings: In commercial settings such as shopping malls, airports, and stadiums, steel grating decks are used for elevated walkways, mezzanines, and pedestrian bridges to maximize space and facilitate pedestrian traffic.

- Infrastructure Projects: Steel grating decks are utilized in infrastructure projects such as bridges, overpasses, and railway platforms to provide durable and corrosion-resistant flooring solutions that can withstand heavy vehicular and pedestrian traffic.

Elevate Your Projects with Om Engineers (Fabricator)

At Om Engineers (Fabricator), we specialize in designing, fabricating, and installing high-quality steel grating decks that meet the highest standards of safety, durability, and performance. With our expertise and commitment to excellence, we ensure that each project is tailored to the unique needs and specifications of our clients, delivering solutions that exceed expectations.

Contact us today at +91 9922444544 to learn more about our steel grating deck solutions and discover how Om Engineers (Fabricator) can help you elevate your structural projects to new heights of excellence and efficiency. Let’s collaborate to bring your vision to life and create structures that stand the test of time.