Unveiling the Power of PEB Design

In the realm of modern construction, Pre-Engineered Building (PEB) design stands tall as a beacon of innovation, efficiency, and sustainability. In this comprehensive guide, we delve into the intricacies of PEB design, addressing common questions, outlining the design process, exploring key elements, and unveiling specifications to help you harness the full potential of PEB structures.

Discover our innovative new project on Google Business Profile, showcasing our commitment to excellence and customer satisfaction.

What is PEB Design?

Pre-Engineered Building (PEB) design is a revolutionary approach to construction that involves the fabrication of building components off-site, followed by their assembly on-site. PEB structures are characterized by their efficiency, cost-effectiveness, and rapid construction timeline, making them a preferred choice for a wide range of applications including warehouses, industrial facilities, commercial buildings, and more.

How we Design a PEB Shed?

Designing a PEB shed involves several key steps:

- Site Assessment: Evaluate site conditions, terrain, and environmental factors to determine the optimal location and orientation for the PEB shed.

- Functional Requirements: Identify the specific functional requirements of the shed, such as size, layout, load-bearing capacity, and operational needs.

- Architectural Design: Develop the architectural design, considering factors such as aesthetics, space utilization, and building codes.

- Structural Design: Engineer the structural components of the shed, including columns, beams, and roof trusses, to ensure structural integrity and safety.

- Material Selection: Choose high-quality materials that meet performance standards and specifications while adhering to budgetary constraints.

- Integration of Services: Incorporate essential services such as HVAC, plumbing, and electrical systems into the design to optimize functionality and efficiency.

- Review and Approval: Collaborate with stakeholders to review the design, address any concerns or modifications, and obtain necessary approvals before proceeding to fabrication and construction.

What are the Elements of PEB?

The key elements of a PEB structure include:

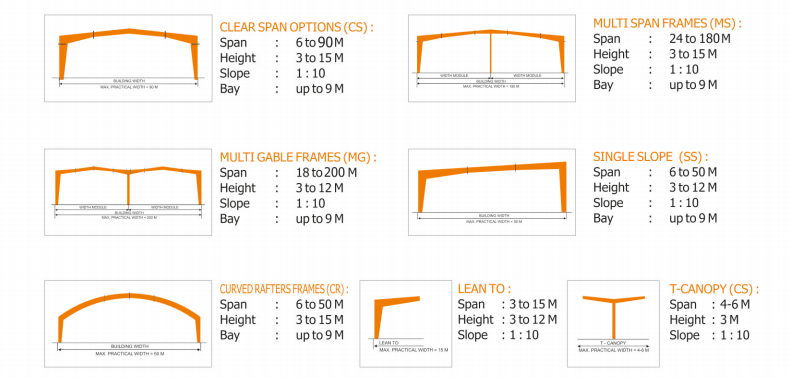

- Primary Framing: Consists of rigid frames comprising columns and rafters that support the weight of the building and transfer loads to the foundation.

- Secondary Framing: Includes elements such as purlins, eave struts, and girts that provide additional support and stability to the structure.

- Roof and Wall Panels: Prefabricated panels made of steel or other materials that form the exterior envelope of the building, offering protection against weather elements and enhancing insulation.

- Accessories: Various accessories such as doors, windows, vents, and skylights that enhance functionality and aesthetics.

What are the Specifications of PEB?

Specifications of PEB structures may vary depending on factors such as building type, location, and client requirements. However, common specifications include:

- Design Wind Load

- Design Snow Load

- Roof Slope

- Bay Spacing

- Clear Height

- Roof and Wall Panel Thickness

- Coating Specifications

Ready to unleash the potential of PEB design for your next construction project? Contact us today at +919922444544 for expert guidance, personalized solutions, and seamless execution tailored to your needs.

Embrace the efficiency, versatility, and sustainability of PEB structures and embark on a journey towards unparalleled success in construction. Experience the transformative power of PEB design and elevate your projects to new heights of excellence.