Strength and Efficiency of Industrial PEB Structures

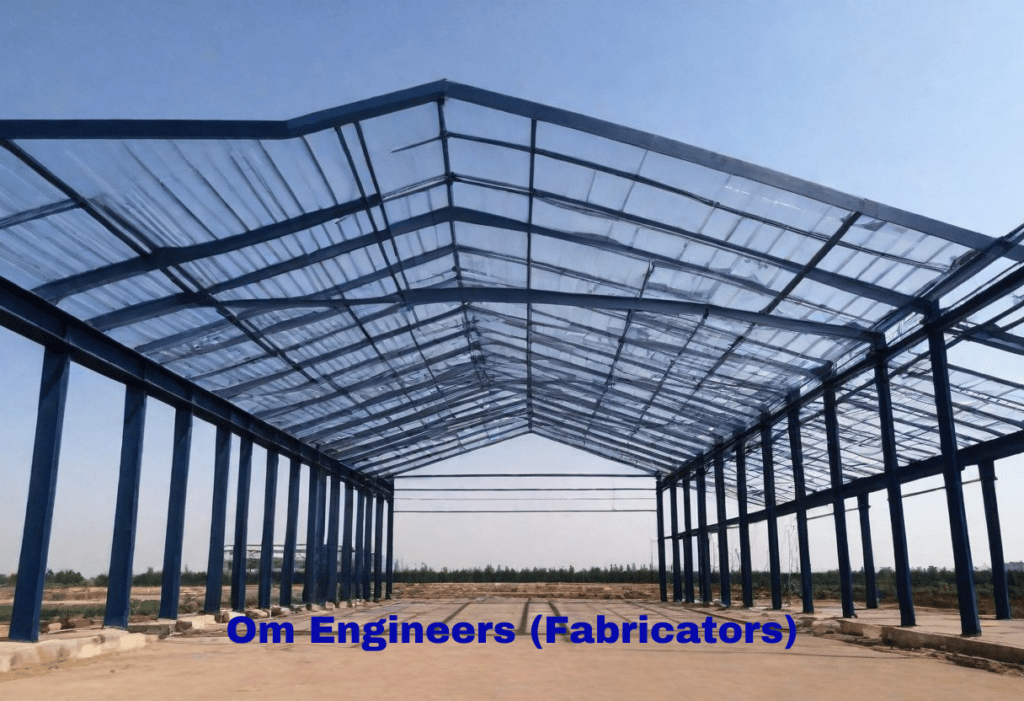

In the realm of industrial construction, Pre-Engineered Buildings (PEB) have emerged as a hallmark of efficiency, durability, and cost-effectiveness. These structures, characterized by their pre-designed and pre-fabricated components, offer unparalleled versatility and speed of construction. In this comprehensive guide, we unravel the intricacies of Industrial PEB Structures, addressing common questions and shedding light on their key features.

Discover our innovative new project on Google Business Profile, showcasing our commitment to excellence and customer satisfaction.

What Steel is Used in PEB?

PEB structures are primarily constructed using high-quality structural steel. This steel is specifically engineered to withstand heavy loads, adverse weather conditions, and other challenges encountered in industrial environments. The use of structural steel ensures superior strength, durability, and structural integrity, making it an ideal choice for PEB construction.

What Materials are Used in PEB?

In addition to structural steel, PEB structures may incorporate various other materials to fulfill specific functional and aesthetic requirements. These materials can include:

- Roofing and Cladding Materials: Typically made of high-quality metal sheets or composite panels, these materials provide weatherproofing, insulation, and aesthetic appeal to the building envelope.

- Insulation Materials: To enhance thermal efficiency and energy conservation, insulation materials such as fiberglass, mineral wool, or foam boards may be incorporated into PEB structures.

- Foundation Materials: Depending on site conditions and structural requirements, PEB structures may utilize materials such as concrete for foundations to ensure stability and load-bearing capacity.

What Grade of Steel is Used in PEB?

The grade of steel used in PEB structures typically varies based on factors such as design specifications, structural requirements, and environmental considerations. Common grades of structural steel used in PEB construction include ASTM A572, ASTM A36, and ASTM A992. These grades are selected for their high strength, weldability, and suitability for structural applications.

What is the Maximum Height of PEB Structure?

The maximum height of a PEB structure can vary depending on several factors, including the design configuration, structural system, and local building codes and regulations. However, PEB structures are capable of accommodating a wide range of heights, from single-story warehouses to multi-level industrial facilities. Engineering expertise and careful design considerations are essential to determine the optimal height for a PEB structure while ensuring structural stability and functionality.

Ready to elevate your industrial infrastructure with PEB structures? Contact us today at +919922444544 for expert consultation, customized solutions, and seamless implementation of your industrial projects.

Experience the efficiency, durability, and versatility of Industrial PEB Structures, and unlock the potential for growth and success in your industrial ventures. Transform your vision into reality with our comprehensive PEB solutions tailored to your specific needs and requirements.