WPC Sheet Design Cutting: Innovating Architectural Excellence

In the realm of modern architectural fabrication, WPC (Wood Plastic Composite) sheet design cutting has revolutionized the way designers and fabricators create stunning interior and exterior elements. With its versatility, durability, and aesthetic appeal, WPC sheets have become a popular choice for a wide range of applications, from decorative panels to intricate facade details. In this article, we delve into the art of WPC sheet design cutting, exploring its benefits, applications, and the expertise offered by Om Engineers (Fabricator) in elevating architectural excellence.

Understanding WPC Sheet Design Cutting

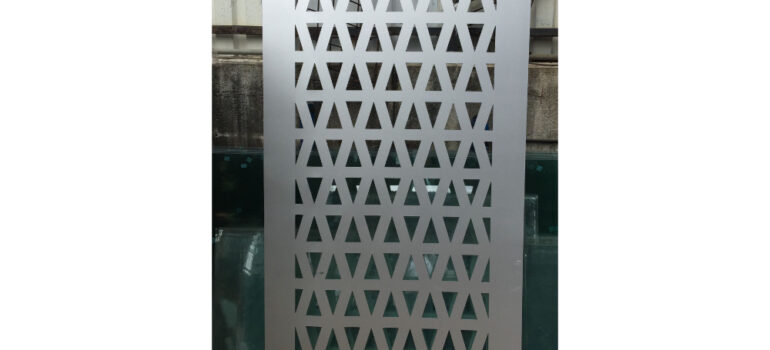

WPC sheets are composite materials made from a combination of wood fibers and plastic polymers, offering the natural look and feel of wood with enhanced durability and weather resistance. WPC sheet design cutting involves precision cutting and shaping of these sheets using advanced CNC (Computer Numerical Control) machinery. This process allows fabricators to create intricate patterns, textures, and shapes, bringing design visions to life with unparalleled precision and accuracy.

The Advantages of WPC Sheet Design Cutting

WPC sheet design cutting offers numerous benefits that make it a preferred choice for architects, designers, and fabricators:

- Versatility: WPC sheets can be cut and shaped into virtually any design, from simple geometric patterns to intricate motifs and custom configurations, allowing for endless creative possibilities in architectural design.

- Durability: WPC sheets are highly durable and resistant to moisture, rot, and decay, making them suitable for both interior and exterior applications, including wall cladding, facade detailing, furniture, and decorative elements.

- Ease of Installation: WPC sheets are lightweight and easy to handle, reducing installation time and labor costs compared to traditional building materials such as wood or stone.

- Low Maintenance: WPC sheets require minimal maintenance and upkeep, retaining their appearance and structural integrity for years to come with simple cleaning and occasional maintenance.

Applications of WPC Sheet Design Cutting

WPC sheet design cutting finds applications across various sectors of architectural design and fabrication:

- Interior Decor: WPC sheets are used to create decorative wall panels, ceiling panels, room dividers, and furniture components, adding warmth, texture, and visual interest to interior spaces.

- Exterior Cladding: WPC sheets are utilized as exterior cladding materials for building facades, providing a durable and aesthetically pleasing alternative to traditional materials such as brick or concrete.

- Signage and Branding: WPC sheets can be CNC-cut to create custom signage, logos, and branding elements for commercial establishments, enhancing brand visibility and identity.

Elevate Your Architecture with Om Engineers (Fabricator)

At Om Engineers (Fabricator), we specialize in delivering exceptional WPC sheet design cutting solutions that elevate architectural excellence to new heights. Our state-of-the-art CNC machinery and skilled craftsmen ensure precision, quality, and attention to detail in every project. Whether you’re designing a residential, commercial, or institutional space, we collaborate closely with you to bring your design visions to life with unmatched precision and craftsmanship.

Ready to transform your architectural projects with WPC sheet design cutting? Contact Om Engineers (Fabricator) today at +91 9922444544 to discuss your requirements and discover how we can add value to your projects with our expertise and dedication to excellence. Let’s embark on a journey of innovation and creativity together, creating spaces that inspire and delight.

No post found