Industrial Sheds: A Comprehensive Guide

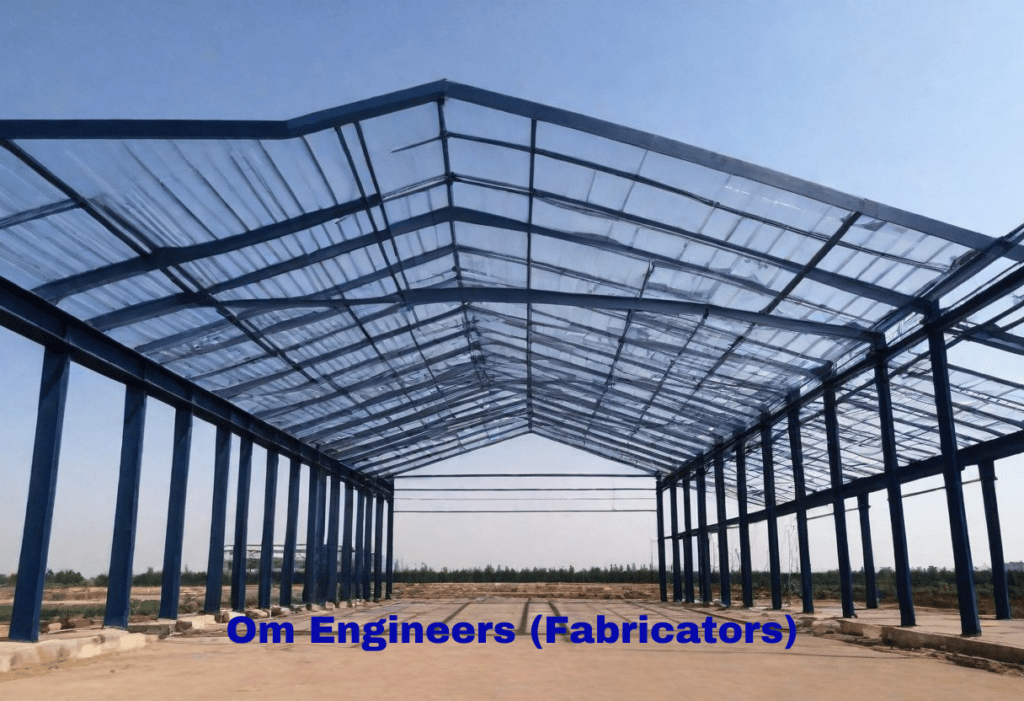

Industrial sheds stand as the backbone of manufacturing and warehousing facilities, providing essential shelter and functionality for a diverse range of industrial operations. As pioneers in fabricating sturdy and reliable industrial sheds, Om Engineers brings forth a wealth of expertise and innovation to meet the evolving needs of businesses across various sectors. In this detailed guide, we delve into the world of industrial sheds, exploring their features, applications, and the unrivaled solutions offered by Om Engineers.

Understanding Industrial Sheds

Industrial sheds, also known as industrial buildings or warehouses, are large structures designed to accommodate manufacturing processes, storage, logistics, and distribution activities. These versatile facilities are characterized by their spacious interiors, high ceilings, and robust construction, which are essential for housing heavy machinery, equipment, raw materials, and finished goods.

Applications of Industrial Sheds

Industrial sheds find applications across a wide spectrum of industries, including:

- Manufacturing: Industrial sheds provide the ideal environment for manufacturing processes, allowing businesses to efficiently produce goods while maintaining quality and safety standards.

- Warehousing: With their expansive floor space and customizable layouts, industrial sheds serve as efficient warehousing facilities for storing inventory, materials, and equipment.

- Logistics and Distribution: Industrial sheds play a crucial role in the logistics and distribution chain, serving as distribution centers, fulfillment hubs, and transit points for goods and commodities.

- Workshops and Garages: Industrial sheds are often used as workshops and garages for vehicle maintenance, repairs, and servicing in automotive, transportation, and heavy equipment industries.

Features of Om Engineers Industrial Sheds

Om Engineers (Fabricator) specializes in designing and fabricating industrial sheds tailored to the unique requirements of each client. Our industrial sheds boast several key features and benefits:

- Structural Integrity: Our industrial sheds are engineered for durability and structural integrity, ensuring they withstand harsh weather conditions, heavy loads, and seismic activity.

- Customization: We offer fully customizable industrial shed solutions, allowing clients to specify dimensions, layouts, roof types, cladding materials, and additional features to suit their specific needs.

- Quality Materials: We use high-quality materials sourced from trusted suppliers to fabricate industrial sheds that meet the highest standards of quality and reliability.

- Cost-Effectiveness: Our industrial sheds are designed for cost-effectiveness, offering efficient use of space, energy-saving features, and low maintenance requirements to maximize return on investment.

Elevate Your Industrial Infrastructure with Om Engineers

At Om Engineers (Fabricator), we are committed to delivering innovative and reliable industrial shed solutions that exceed expectations. With our expertise, dedication, and customer-centric approach, we have established ourselves as a trusted partner for businesses seeking superior industrial infrastructure solutions.

To learn more about our industrial shed offerings and how we can cater to your specific requirements, contact us today at +91 9922444544. Let Om Engineers (Fabricator) be your partner in building robust and efficient industrial facilities that drive success and growth for your business.